About us

Our story begins in the year 1972, and since then, at ENUSA, we have been working to provide quality, safety, and efficiency to our clients, always adhering to ethical and sustainable values.

We are the ENUSA Group

Comprising ENUSA as the parent company, dedicated to the nuclear business, EMGRISA, focused on the environmental business, and ETSA, dedicated to the logistics business.

Our pillars

Safety, environmental respect, quality, and R&D+i constitute our most valuable pillars. Taking another step towards excellence in management, we have integrated corporate social responsibility into our decisions and actions.

Sustainability

We are committed to responsible management that takes into account the impacts on people and the environment.

Security

Our premise is "safety first". Safety is integrated in all our activities.

R&D+I

We integrate the most innovative technology into our equipment and processes to improve the product and levels of quality and safety.

Equality and diversity

We believe in responsible management that considers the impacts on people and the environment. We work towards a fairer future.

Quality

We prioritize quality as a strategic factor and a fundamental pillar in our activities, implementing management systems and continuous improvement.

Digital transformation

Digitalization should not be an end but a means to achieve our objectives outlined by a strategic vision of our business.

Our values

Our purpose is to develop innovative nuclear and environmental solutions globally, contributing to the sustainable progress of society.

Security

To ensure trust in our business, we carry out our activities with the highest conditions of efficiency, guarantee, and reliability.

Flexibility

We know that the ability to anticipate and adapt to changes in the environment and the needs of our clients is the key to ensuring success.

Innovation

We understand innovation as a factor of progress and a guarantee for the future. We value entrepreneurship and the pursuit of creative and efficient solutions.

Commitment

We are committed to the Sustainable Development Goals (SDGs), especially in the environmental, social, equality, and diversity dimensions.

Collaboration

We believe in the importance of a collaborative environment that promotes continuous learning and the desire for improvement.

Active projects

The SEPI Group is a Public Law entity whose activities adhere to private legal regulations, attached to the Ministry of Finance and Public Administrations, with direct dependence on the minister.

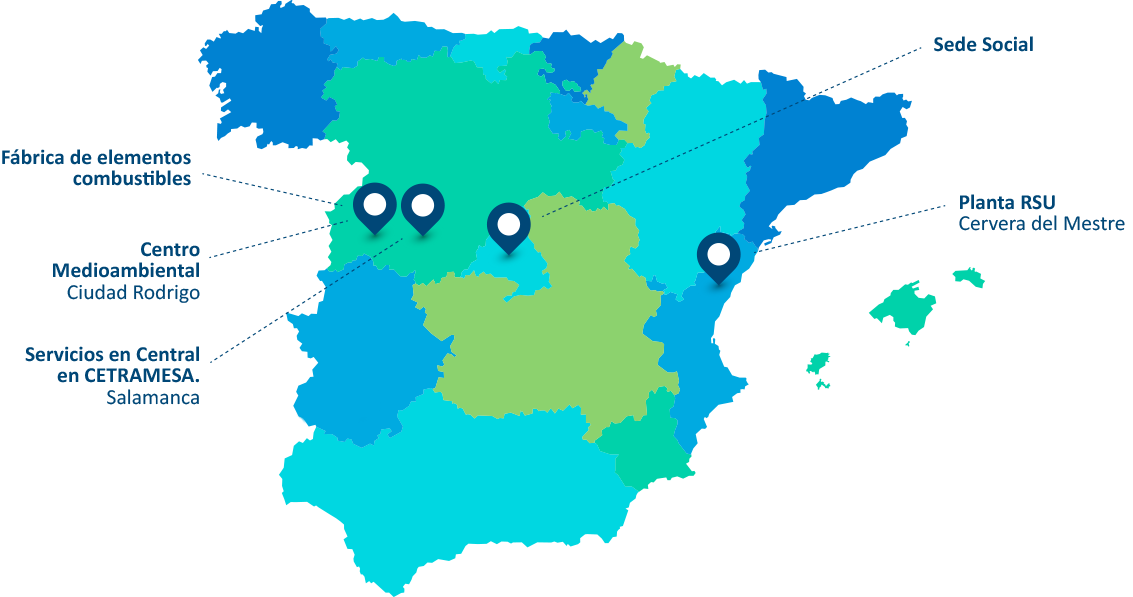

Our location

Our headquarters are located in Madrid. It serves as the registered office where the main governing bodies, including the Board of Directors and the Management Committee of the company, are situated. Additionally, central and administrative services, Institutional Relations, and the Engineering, Fuel, Uranium Supply, Quality, HR, and Internal Audit Departments are housed here.

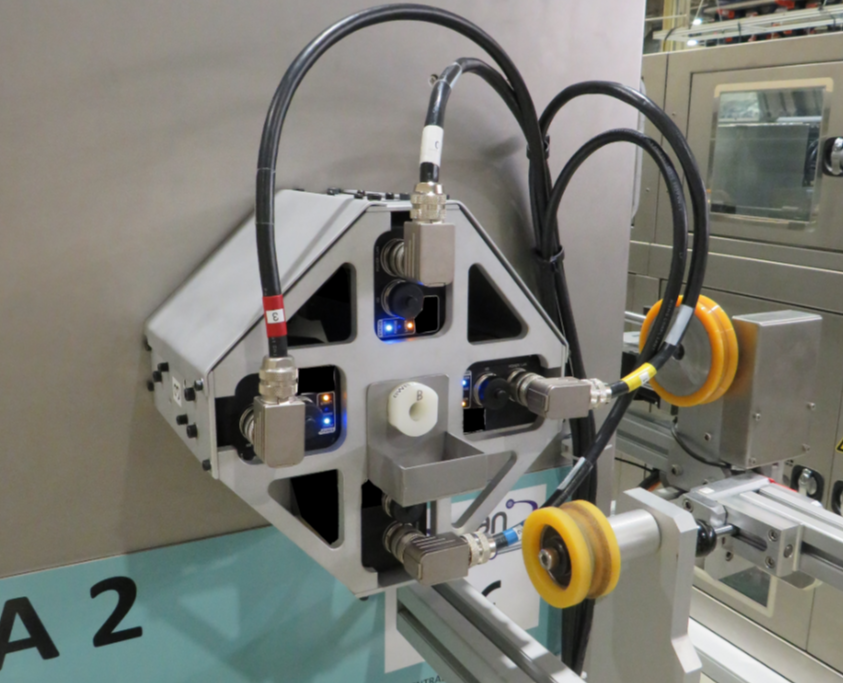

The fuel elements factory in Juzbado

Our factory is one of the most innovative in Europe, incorporating state-of-the-art technology to optimize resources and protect the environment.

The center has a specialized and highly qualified team that covers the entire fuel production cycle: uranium supply, storage, component logistics, fuel manufacturing, product quality control, development of equipment for PWR, BWR, and VVER products, and management of logistics and distribution to power plants in Spain and some European countries.

The factory has a maximum annual production capacity of around 500 tons of uranium in accordance with the current Operating and Manufacturing Authorizations, with a maximum enrichment of 5% in 235U.

Other activities carried out in the factory include Quality Engineering, which controls and certifies the final product quality, Process Engineering that develops equipment and processes for the manufacturing of different products, and Fuel Services that coordinate inspection and repair campaigns.

Safety is the main pillar of the company, and for this reason, the factory has a Safety Department that ensures the correct operation of the facility from a nuclear, physical, radiological, and environmental perspective. The company continuously invests in equipment renewal, process optimization, and improvement of safety systems.

The factory has six specialized laboratories that monitor the manufacturing process, maintain environmental surveillance of the surroundings, and control personnel dosimetry. These laboratories adhere to strict criteria of quality, independence, expertise, professionalism, safety, and environmental respect, certified by ENAC according to ISO 17.025 and by AENOR according to ISO 9.002 standards.

Saelices el Chico Center (Ciudad Rodrigo)

In the year 2000, the exploitation activities in the former uranium mines of Saelices el Chico concluded, and the dismantling of the radioactive processing facilities and the restoration of the natural space affected by mining operations immediately began.

In 2003, the dismantling of the Elefante Plant and its leaching pads concluded, and in 2009, the final restoration of the mining operations was completed. Both projects are currently in the corresponding surveillance and control period.

Solid Urban Waste Plant in Maestre de Cervera, Castellón

It is a complex consisting of the most advanced bio-technological plant in Spain for the valorization of MSW and similar wastes through bio-drying and accelerated oxidation.

It serves 49 municipalities with a maximum seasonal population of 300,000 inhabitants and, on average, can process 120,000 tons per year.